CNC PUNCHING

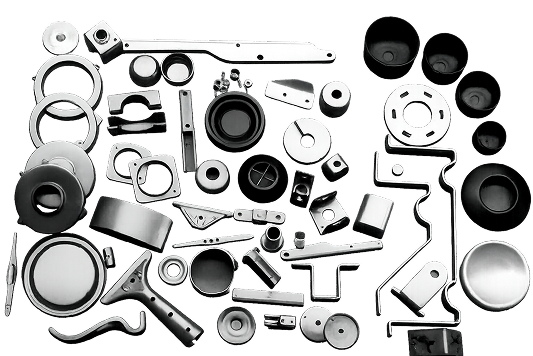

Explore the CNC Punching Services Haake Manufacturing uses to produce many different types of parts for your most demanding tasks.

CNC PUNCHING OVERVIEW

There are a lot of ways to shape sheet metal, and none of them are necessarily wrong. But there are different methods that work best for different kinds of materials, tolerances, and the functions of the parts you’ll be producing.

CNC Punching works well as a high-efficiency solution for thinner materials and parts that require formed features.

Benefits of CNC PUNCHING

CNC punching delivers high-speed production for thin sheet metal, cost efficiency at higher volumes, and the ability to form features like louvers, extrusions, and countersinks in a single operation.

Here are a few of the biggest things to consider as you’re choosing a metal cutting process and why CNC punching is becoming a go-to choice for manufacturers.

When to Consider CNC PUNCHING

Material Type

Well-suited for mild steel, stainless, aluminum, and galvanized materials; process parameters adjust automatically by material.

Material Thickness

Highly efficient on thin to medium gauges; performance and speed decrease as thickness increases, where alternative methods may be evaluated.

Tolerance Requirements

Capable of tight, repeatable tolerances with minimal variation part-to-part.

Edge Quality

Produces smooth edges with minimal burrs; nitrogen cutting eliminates oxidation, improving weld and finish quality.

Geometry Complexity

Excels at complex profiles and fine features with no tooling constraints.

Production Volume

Minimal setup makes it ideal for prototypes and low-to-mid volumes; remains viable for production depending on part complexity.

Secondary Operations

Clean edges reduce deburring; consistent cuts improve downstream welding, bending, and coating processes.

Total Cost

Reduced setup, fewer secondary steps, and faster turnaround often lower total project cost.

HAAKE’S APPROACH TO CNC PUNCHING

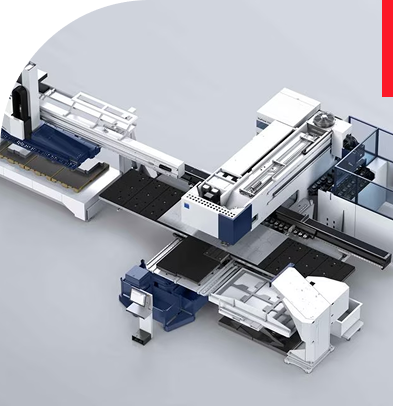

Haake Manufacturing’s CNC punching technology permits complex, three-dimensional processing with the goal of complete processing on one machine. The punching head on each machine has full, 360-degree rotation.

Custom-shaped Materials & Tolerances to Fit What You Need

Haake can work with a variety of materials during the CNC punching process. We’ve also tested a range of thicknesses, and have found 0.1” to 0.125” to be the ideal top range we punch for.

Reduce Lead Times WITH Secondary Machining

We offer these secondary processes as part of our CNC punching, which directly improves efficiency, accuracy, and total cost.

- Countersink

- Spotface

- High-speed tapping

- Extrude

- Lance

- High-speed forming

- High-speed line marking

combination solutions for Your Toughest Jobs

Sometimes, you have a challenging job that would benefit from two metal stamping processes. We’re a shop that embraces these projects, and we are the only job shop in the St. Louis region that has punch and laser processing on the same machine.

Our combination machine has all the benefits of both punching and laser processing. This combination processing allows us to produce parts quickly without the added time and cost associated with moving the parts between separate machines.

Advanced Laser Technology for Uncompromising Quality

We’ve chosen Trumpf’s equipment for laser cutting because they have been developing laser technology since 1923.

They have the learnings, technology, and resources to optimize upstream and downstream laser cutting processes, which means you get the most innovative equipment with the best outcomes.

CNC Punching in the Real World

Construction

Mounting plates, brackets, and access panels

Furniture

Metal frames, brackets, drawer components

Automotive

Brackets, interior panels, & mounting components

Aerospace

Brackets, clips, and access panels

Aerospace

Cabinet panels, frames, and vented panels

Interested in starting a CNC Punching Project?

Fill out this form, and someone from our team we’ll get back to you as soon as possible!