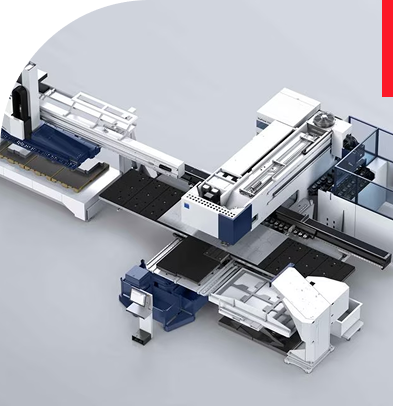

CNC Punch / Laser Combination

CNC LASER CUTTING OVERVIEW

There are many methods for metal cutting, and the one you choose depends on the types of materials you want to use, the complexities of the part you need, what your part will be used for, and even how quickly you need your component manufactured.

CNC Laser Cutting embraces many different types of materials, it can hold very specific, tight tolerances, and it offers smooth finishes with clean edges through CNC-controlled beams.

Benefits of CNC PUNCH / Laser Combination

CNC punch/laser combination machines bring laser cutting precision and punching efficiency into a single, integrated process, allowing manufacturers to produce complex sheet-metal parts faster, more accurately, and at a lower total cost.

By combining both technologies in one setup, parts can be punched, formed, marked, and laser cut without repositioning, ensuring tight feature alignment and consistent quality from start to finish.

If you’re wondering if a CNC Punch/Laser combination is the right fit for you, consider these factors.

When to Consider CNC Laser Cutting

Material Thickness

Punching handles thin material efficiently while the laser manages profile cuts.

Feature Types

Punching creates forms (louvers, extrusions), laser cuts complex geometry.

Tolerance Requirements

Capable of tight, repeatable tolerances with minimal variation part-to-part.

Positional Accuracy

All operations reference a single datum for precise feature-to-feature accuracy.

Secondary Operations

Combining operations reduces handling, setups, and downstream machining.

HAAKE’S APPROACH TO CNC PUNCH/Laser Combination

Haake Manufacturing is one of the few job shops in the St. Louis region with punch and laser processing on the same machine. This integrated capability combines forming and contouring with laser cutting in a single workflow, reducing handling, shortening cycle times, and lowering overall production cost.

Custom-shaped Materials & Tolerances to Fit What You Need

Haake can work with a variety of materials during the CNC punch/laser combination process. We’ve also tested a range of thicknesses, and we have found 0.1 to 0.125mm to be the ideal range we punch for.

Reduce Lead Times with secondary machining

We offer these secondary processes as part of our CNC punching, which directly improves efficiency, accuracy, and total cost.

- Countersink

- Spotface

- High-speed tapping

- Extrude

- Lance

- High-speed forming

- High-speed line marking

Advanced Laser Technology For Uncompromising Quality

We’ve chosen Trumpf’s equipment for laser cutting because they have been developing laser technology since 1923.

They have the learnings, technology, and resources to optimize upstream and downstream laser cutting processes, which means you get the most innovative equipment with the best outcomes.

CNC Punch/Laser Combination In The Real World

CNC Punch/Laser Combination machines are ideal for mixed-feature, precision parts used across these industries:

Construction

Mounting plates, brackets, and access panels

Furniture

Metal frames, brackets, drawer components

Automotive

Brackets, interior panels, & mounting components

Aerospace

Brackets, clips, and access panels

Appliances

Cabinet panels, frames, and vented panels

Interested in starting a CNC Punch / Laser project?

Fill out this form, and someone from our team we’ll get back to you as soon as possible!