Powder Coating

Haake Manufacturing offers state-of-the-art industrial powder coating services that allows for quick color changes and smooth, continuous coating.

Powder Coating Overview

If you’re looking for a robust, repeatable finish for your metal that balances performance and appearance the powder coating method may be best for you.

The power coating process is unique with its use of a dry, electrostatically charged powder that is cured with heat, and applied to objects for a durable, consistent finish. The finishes can be glossy or matte and bring a higher level of strength and style than you generally see with other methods.

Benefits of Powder Coating

Powder coating is typically selected when durability, consistency, and throughput are high priorities. With proper pretreatment, it offers a repeatable finishing solution for demanding applications.

Here are a few of the biggest things to consider as you explore the powder coating method.

When to Consider Powder Coating

Base Material COmpatibility

Well suited for steel, aluminum, and galvanized materials; requires proper cleaning and pretreatment for optimal adhesion.

Corrosion Resistance Requirements

Provides strong corrosion protection when paired with proper pretreatment (e.g., multi-stage wash, zirconium chemistry).

Finish Durability

Produces a tough, resilient coating that outperforms most liquid paints in mechanical durability.

Surface Appearance

Delivers consistent film thickness with minimal defects; supports smooth, textured, and specialty finishes.

Film Thickness COntrol

Electrostatic application enables repeatable thickness control across production runs.

Part Geometry

Performs well on most geometries, though deep recesses may require process adjustments to ensure coverage.

Production Volume

Highly efficient for medium to high volumes; parts can be handled immediately after curing.

Secondary Operations

Reduced rework and touch-up compared to liquid paint; masking may be required for tight-tolerance features.

Environmental & Regulatory Factors

Typically VOC-free and safer to handle than liquid coatings, simplifying compliance.

Total Cost

Lower waste, high transfer efficiency, and reduced rework often result in lower total cost over time.

HAAKE’S APPROACH TO POWDER COATING

Haake Manufacturing’s powder coating operation is not just a finishing step. It’s a fully automated, controlled, high-quality service where pretreatment, wash stages, and curing all contribute to durability and appearance.

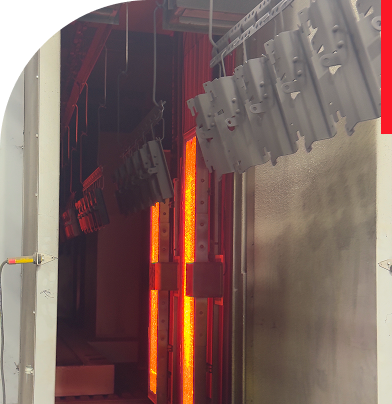

Enhanced Speed & Quality Through Our Pre-Process Infrared System

Haake’s pre-process infrared (IR) system is a major advantage when it comes to choosing a finishing process because the IR system improves process speed, consistency, energy efficiency, and overall quality control by ensuring parts are properly prepared before coating.

High efficiency environments benefit from powder coating because it heats up products faster, it’s ideal for heavier, complex parts, and leads to lower defect rates.

Better Adhesion Using Our 6-STATION GAT WASH SYSTEM

The more wash tanks you have and that you use in your process, the better the chemical pretreatment. Our six wash system means improved powder adhesion and more consistent coating performance.

Environmentally-Conscience Chemical Pre-treatment

Sometimes, you have a challenging job that would benefit from two metal stamping processes. We’re a shop that embraces these projects, and we are the only job shop in the St. Louis region that has punch and laser processing on the same machine.

Our combination machine has all the benefits of both punching and laser processing. This combination processing allows us to produce parts quickly without the added time and cost associated with moving the parts between separate machines.

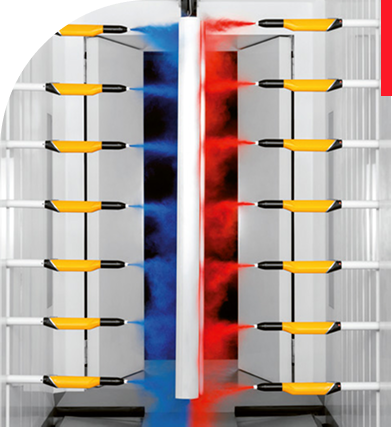

We use the GEMA Powder Coating System

Gema Powder Coating is a state-of-the-art application technology. Its automatic powder gun applicators can control film and build application parameters precisely to within your specs. Other benefits include:

- Multiple color capabilities

- No material contamination

- Proper coating dryness when stored

- Repetitive production runs of same parts and specs

- Reduced powder contamination between the colors

- Reduced “orange peel”, back ionization, picture frame effect and other defects

- Continuous coating for a higher efficiency

Powder Coating

In The Real World

OUTDOOR FURNITURE & OTHER FEATURES

Metal fencing and gates, outdoor light poles, and patio furniture frames

Automotive parts

Suspension components, engine brackets, and underbody shields

Architectural elements

Exterior metal panels, balcony and stair railings, structural columns

Decorative home items

Light fixtures, furniture accents, metal shelving and storage

Interested in starting a Coating project?

Fill out this form, and someone from our team we’ll get back to you as soon as possible!