CNC LASER CUTTING

Learn how Haake Manufacturing employs innovative metal laser cutting equipment to give customers quick turnaround and competitive pricing.

CNC LASER CUTTING OVERVIEW

There are many methods for metal cutting, and the one you choose depends on the types of materials you want to use, the complexities of the part you need, what your part will be used for, and even how quickly you need your component manufactured.

CNC Laser Cutting embraces many different types of materials, it can hold very specific, tight tolerances, and it offers smooth finishes with clean edges through CNC-controlled beams.

Benefits of CNC LASER CUTTING

CNC laser cutting brings unmatched precision when designing parts for function and aesthetics.

Here are a few of the biggest things to consider as you’re choosing a metal cutting process that suits your needs and why CNC laser cutting is becoming the preferred choice for manufacturers.

When to Consider CNC Laser Cutting

Material Type & Thickness

CNC laser cutting excels on thin to medium gauge metals and handles a wide range of alloys. Cutting speed and edge quality vary with thickness, so this directly affects feasibility and efficiency.

Tolerance & Edge Quality Requirements

Lasers provide tight, repeatable tolerances and smooth edges. Nitrogen cutting eliminates oxidation, improving weldability and surface finish for coating or assembly.

Production Volume

Laser cutting requires minimal setup and no tooling, making it ideal for prototypes, low-to-mid volumes, and frequent design changes. Very high volumes may favor punching for cost efficiency.

Secondary Operations

Clean laser-cut edges reduce deburring and rework. High cut quality improves downstream operations like welding and powder coating, lowering total process time.

Total Cost (Not Just Cut Cost)

Reduced setup, fewer secondary operations, faster turnaround, and lower rework often result in a lower overall project cost.

HAAKE’S APPROACH TO CNC LASER CUTTING

Innovation is at the heart of what we do, and for CNC laser cutting, that means choosing machines with state-of-the-art laser technology that can cut through the thinnest and thickest of metals, giving you the exact performance and look you need.

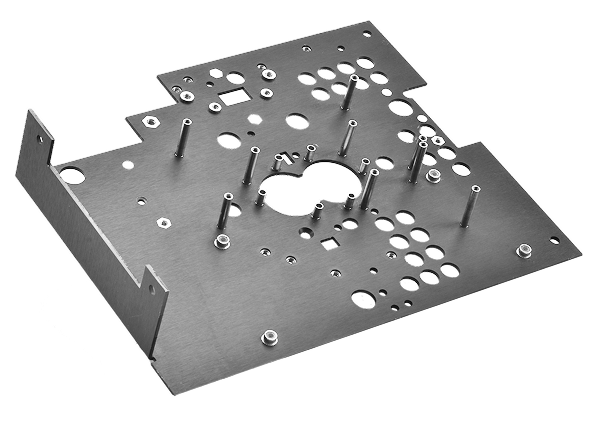

Custom-shaped Materials & Tolerances to Fit What You Need

Haake combines precision laser cutting with customer-specific, tight tolerances on complex geometries.

Our accuracy starts with deep material expertise—working with a wide range of metals to ensure the right fit, finish, and performance for every application.

SpeedYou Can Count On

We help you choose the right laser for the materials you’re using that will ensure fast turnaround and in-spec completion for your metal parts.

Edge Quality That Reduces Secondary Work

With both oxygen and nitrogen laser cutting capabilities, Haake selects the optimal cutting method to achieve the edge quality your part demands.

Nitrogen cutting is often preferred for stainless steel and aluminum, as it eliminates oxidation and preserves material integrity at the cut edge.

This produces cleaner cuts, improved weld preparation, better coating adhesion, and tighter consistency across parts—reducing rework and secondary processing while improving downstream performance.

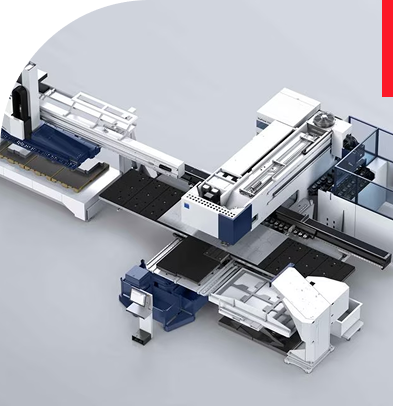

Advanced Laser Technology for Uncompromising Quality

We’ve chosen Trumpf’s equipment for laser cutting because they have been developing laser technology since 1923.

They have the learnings, technology, and resources to optimize upstream and downstream laser cutting processes, which means you get the most innovative equipment with the best outcomes.

CNC Laser Cutting in the Real World

Automotive

Battery trays & EV components

Medical

Stainless panels & trays

Aerospace

Lightweight structural components

Electronics

Chassis and mounting frames

Interested in starting a CNC Laser Cutting project?

Fill out this form, and someone from our team we’ll get back to you as soon as possible!